News

01-01-2024 / 100% green electricity

From January 2024, EMS will hold the certificate

"Guarantee Wind - electricity generated from Dutch wind energy"

with the SMK's eco-label.

This certificate is proof that 100% of EMS electricity consumption comes from Dutch wind energy.

28-10-2023 / New stelcon plates

Replacement stelcon plates without steel edges in production, in collaboration with Hoondert 's-Heerenhoek, the new plates have been placed and the bottom has been provided with a tarp, so that in case of any leakage (diesel) this will not be absorbed into the ground.

Thus, Euro-Mit Staal B.V. complies with the latest environmental law, which will be implemented in 2024.

01-09-2023 / New QHSE manager

After 12.5 years at Euro-Mit Staal B.V., we bid farewell to our QHSE Manager, Mr Peter Bastiaansen. His expertise in the fields of quality, health, safety, and environment has contributed to a safe and sustainable working environment for everyone in the company.

Mr Bastiaansen is going to enjoy his well-deserved retirement and we look to the future with confidence with the appointment of Mr Jasper Ravays as his successor. With his expertise and energy, we will continue our commitment to excellent QHSE standards.

Peter goodbye and Jasper good luck with this new challenge

01-07-2023 / Change of management at EMS

We hereby inform you of the departure of our esteemed colleague, Ms. Mariko Hara, as Managing Director at Euro-Mit-Staal B.V. She has terminated her duties with effect from 1 July 2023. Since her appointment on April 1st, 2021, Ms. Hara has contributed significantly to our company and played an important role in the growth and development of Euro-Mit-Staal B.V.

Ms. Hara will take up a position with Mitsui in her home country of Japan. Due to the urgency of the request, everything had to be arranged quickly. Although we will miss her, we wish her every success in her new challenge and are confident that she will be as successful there as here with us.

To ensure a smooth transition and avoid leadership gaps, Mitsui has carefully searched for a suitable successor. We are pleased to announce that Mr. Tomohiro Noda has been appointed as our new Managing Director. Many of you are familiar with Mr. Noda, as he previously held this position for six years before Ms. Hara took office. His extensive experience and knowledge of Euro-Mit-Staal B.V. will help us seamlessly build on Ms. Hara's work.

We warmly welcome Mr. Noda to his new role and will provide him with all the support he needs to be successful. Together, we will ensure that Euro-Mit-Staal B.V. continues to thrive and grow in the future.

On behalf of the entire team, we would like to thank Ms. Mariko Hara for her dedication, commitment, and leadership. We will miss her warm personality and professionalism. At the same time, we look forward to working successfully with Mr. Tomohiro Noda and his leadership in the years to come.

Good luck, Ms. Hara, and good luck, Mr. Noda

28-03-2023 / New paper tube sawing machine

To improve the Safety and working conditions of the existing paper tube cutting machine, EMS designed and ordered a dedicated machine for sawing cardboard cores in 2022. These cores offer more rigidity and protection to the slitted coil material and are used for thin materials of 0.20 mm thickness. Cardboard cores are standard on the market, but the machines needed to cut them to the desired diameter and width are not widely available. The existing machine at EMS was originally purchased in 1992 at the start of EMS. At that time, this machine complied with the rules and regulations. New or modified machines must comply with certain rules and directives:

- EU machinery directive 2006/42/EC

- Work equipment directive 2009/104/EC

- Certification (CE)

To adapt this machine to the current rules and regulations, many changes had to be made. These changes were not feasible through a "simple" upgrade but required a redesign of the existing machine. Unlike the old one, this new machine is equipped with a circular saw instead of knives.

24 March 2023 it was installed, and the Euro-Mit Staal b.v. team watched while the machine did its job. It was clear that this new machine represented a significant improvement in safety, working conditions and the quality of the sawn paper tubes. This machine is much safer and more reliable than the old core cutter.

All in all, the commissioning of the new core sawer was a success. It is yet another step forward in our continuous pursuit of better and safer working conditions.

22-12-2021 / New grinding machine

Earlier this year, the decision was made to replace the Studer cylindrical grinding machine because of its high costs and less reliability. Our experience showed that this advanced machine was somewhat less suitable for our grinding process. Therefore, we started looking for a grinding machine that meets our requirements, i.e:

- Compact machine

- User-friendly

- Reliable

- Suitable for our grinding process

Eventually, we chose a Palmary cylindrical grinding machine. It is manufactured in Taiwan and has good references. To bridge the time between removing the old and installing the new machine, we temporarily outsourced the grinding of the slitter knives.

On 22 December, 2021, the new grinding machine was installed. The next day the first crates were sharpened with good results.

25-03-2021 / Change of management at EMS

We hereby inform you that Mr T. Noda will hand over his duties as Managing Director of EMS to Mrs M. Hara effective from April 1, 2021. Mr Noda has been Managing Director of EMS for the past 6 years, during this time he has contributed a lot and EMS has blossomed into a progressive company. We wish him all the best in his new position in Tokyo.

And we welcome Mrs Hara in our midst, this is the start of a new period in which EMS will hope to grow further and will be positioned even stronger in the market.

04-01-2021 / Updating our Mini slitter 1

January 4, 2021, we started updating our Mini slitter 1. The Mini slitter has been revised and modernised by several companies, this assures us that we will be able to work with it safely and effectively for the next 10-20 years. Mid-February the machine was available for production again.

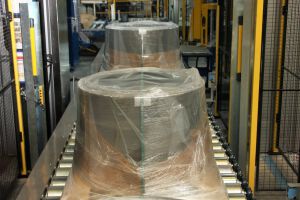

01-03-2020 / Semi-automated coil packing line

In February 2020, we started planning the expansion/renovation of the existing packing line according to the required standards, respecting safety and capacity. For EMS it is important to create a safe and healthy working environment for our employees. The choice of supplier fell on Tallpack international, who could supply us with a packing line that met all our requirements.

The first visible work started in May 2020, our employees followed intensive training and everything came to a positive end with the commissioning of the machine in December 2020.